Have you ever wondered about the technology behind your touch screen? Knowing about the processes of screen bonding technology can empower you to make a better decision when getting an interactive display.

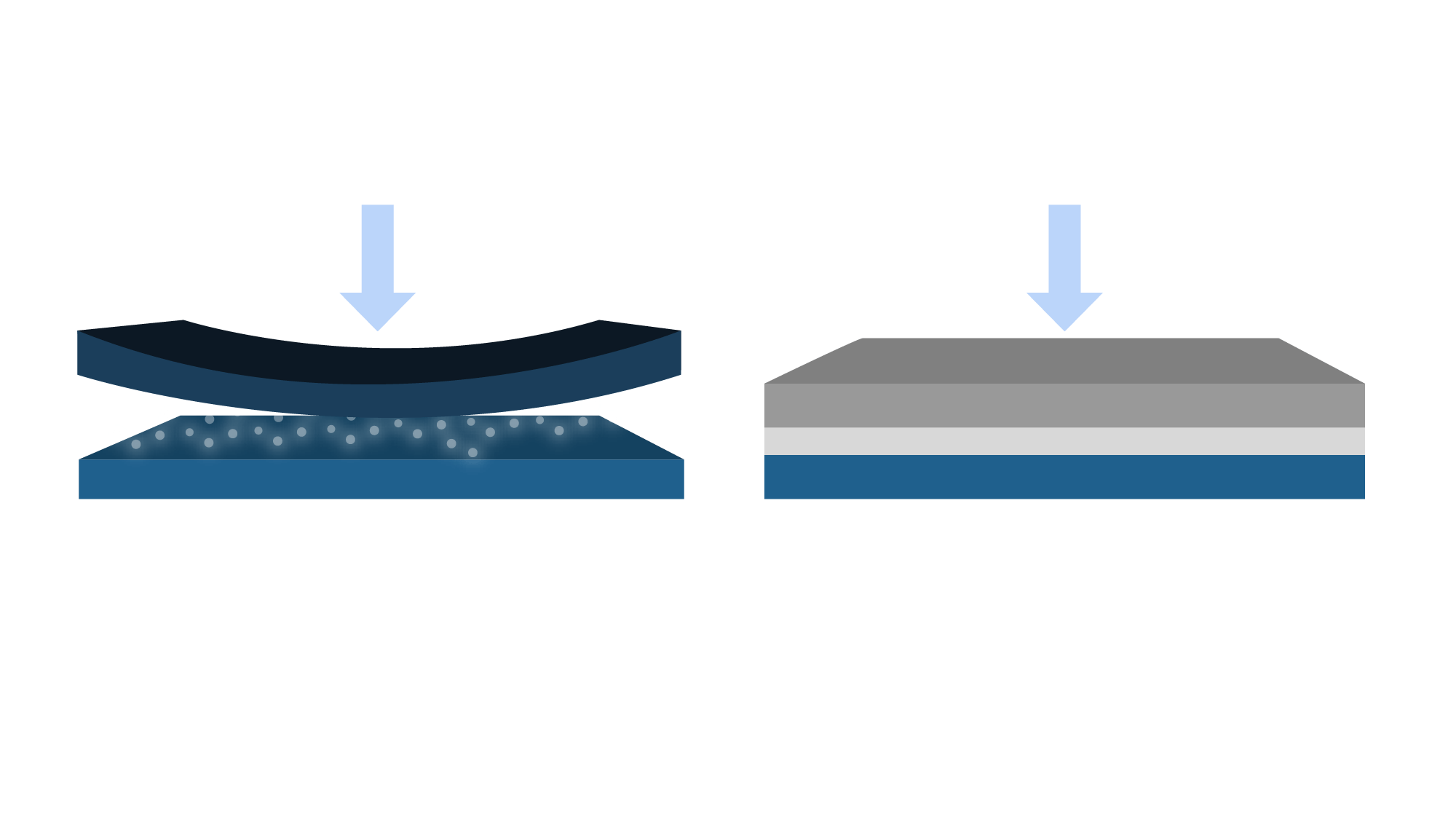

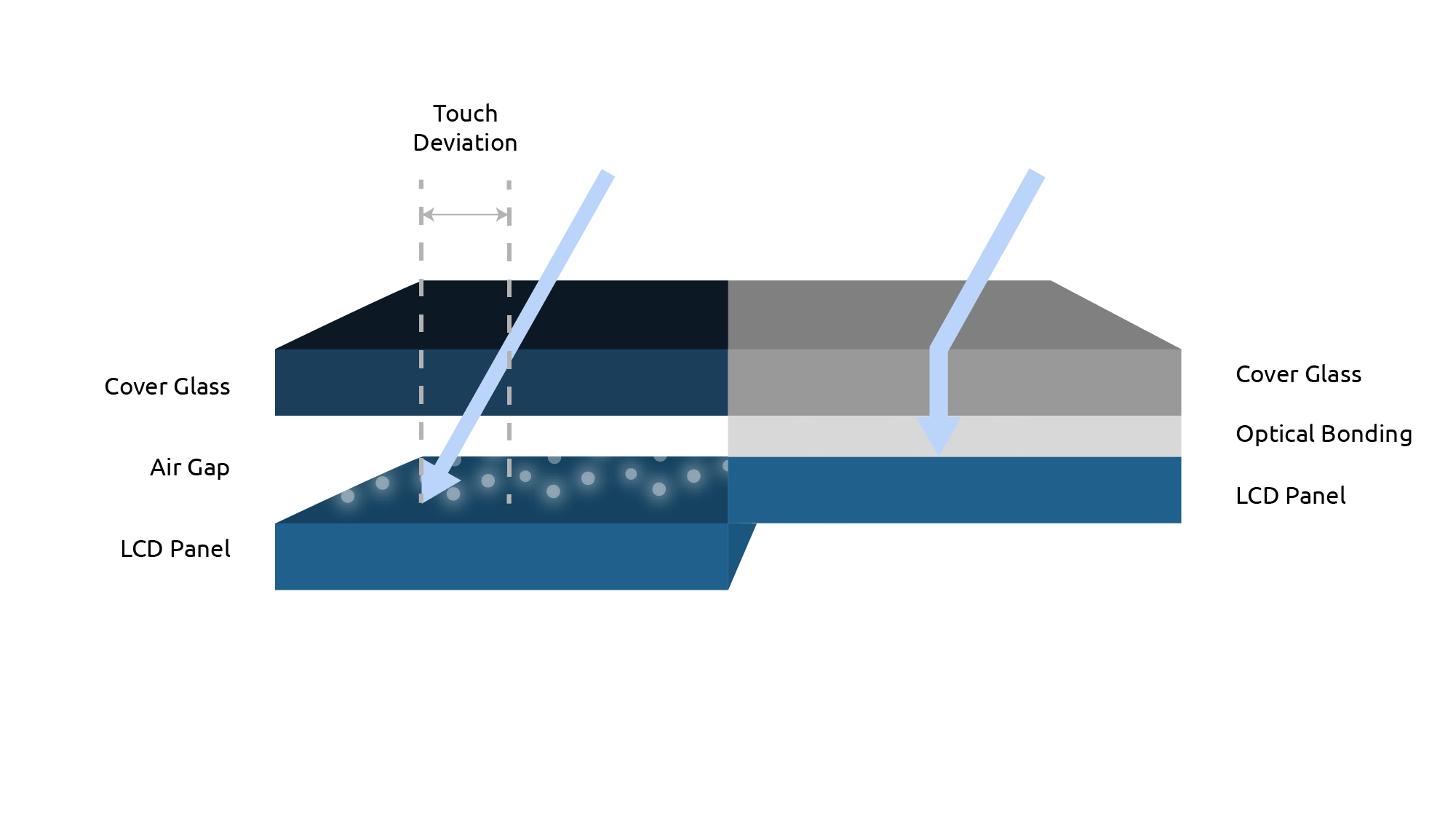

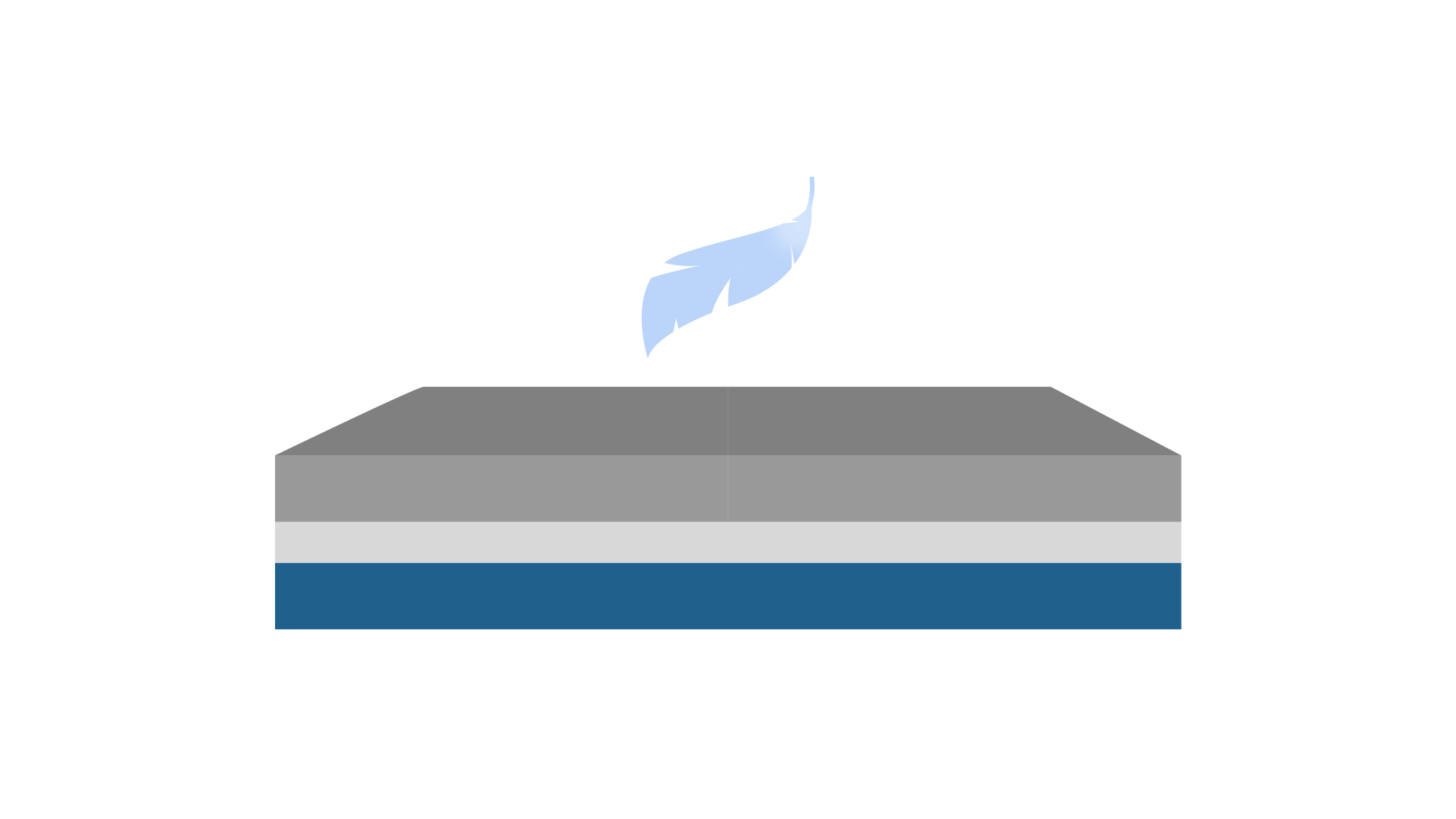

Optical bonding is the process of gluing the touchscreen glass to the LCD cell in order to completely fill the air gap between them. This is done to improve overall performance, decrease the total display weight, and make the touchscreen sturdier.

Traditionally, interactive displays are attached to LCD cells with adhesive tape by the edges of the screen glass. This creates an air gap between the LCD cell and the screen glass that is detrimental to the performance of the display no matter how thin the air gap is. The gap results in setbacks which include a more fragile screen glass, loss of touch accuracy, and a narrower viewing angle, among others.

There are many benefits that come with the optical bonding of a display, all which enhance the performance of the interactive display in varying conditions and allow a greater range of application needs to be met. Here are the top 5 benefits:

Greater durability

The optical bonding process better protects both the cover glass and LCD cell from shock, as the hardened adhesive behind the glass acts as a shock absorber. Shake and shocks are less likely to damage the display and glass, making it an important benefit for transportation applications. In the unlikely event that the glass is damaged, shards of broken glass will remain stuck to the optical adhesive, making it an important benefit for safety reasons in classrooms and meeting rooms.

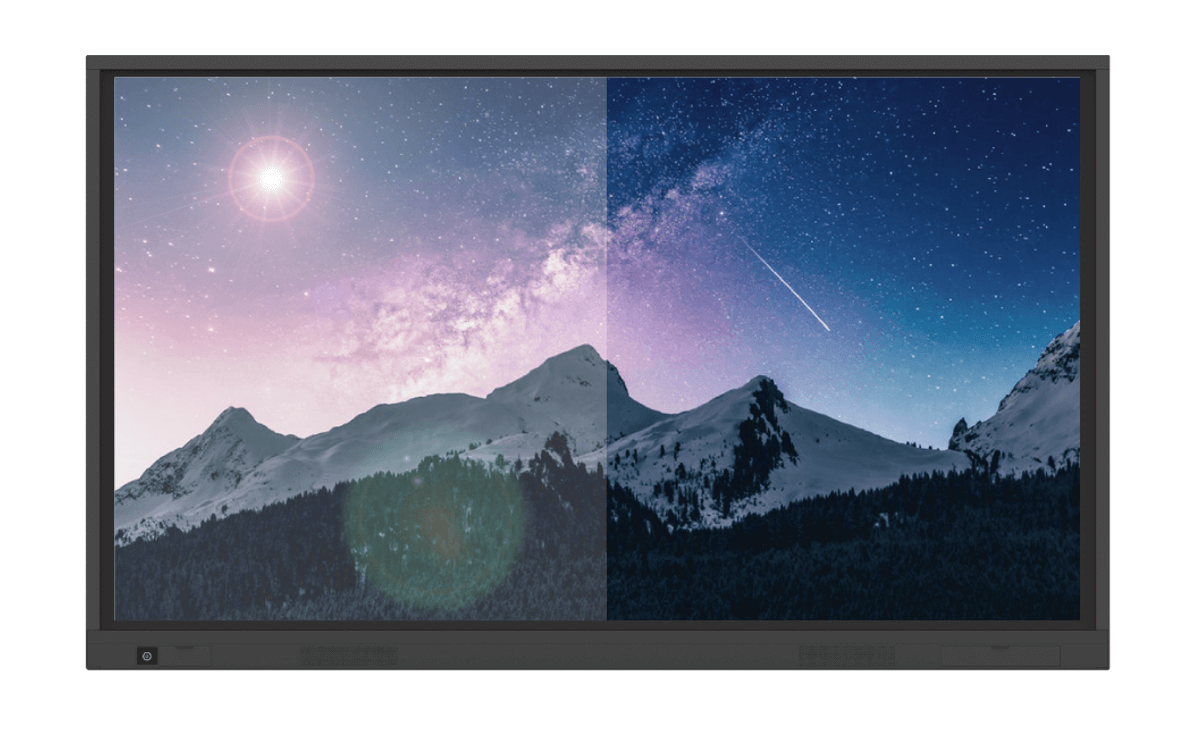

Improved viewing experience

An optically bonded display eliminates the internal reflection between the screen glass and the LCD cell. This results in improved contrast, which enables the display to be better seen in brighter environments. Additionally, the elimination of internal reflection provides a wider viewing angle, allowing the display to be seen more clearly from wider angles in bigger rooms. Whether you have student desks at the front corners of the classroom, or you have to cram seats up the front sides of the meeting room, everyone will be able to see the screen clearly without reflection.

Improved touch experience

Optical bonding reduces parallax, the refraction angle of light which makes the physical location of a pen or finger on the glass appear to be different from the corresponding point on the LCD, depending on your line of sight. This leads to inaccuracy of touch and a poor user experience. Optical bonding removes the air gap, which eliminates parallax to give you the most accurate touch, for the most natural and reliable experience.

Maximum dust & moisture protection

The elimination of the air gap between the cover glass and the LCD panel means that dust and moisture are unable to penetrate the glass and cause condensation on the inner surface of the glass. This is especially important in humid environments, where the high humidity can cause fogging on a non-optically bonded display over time. It is also important for transportation and storage, ensuring the displays remain in an optimal state for a much longer time.

Reduced display weight

The optical bonding process allows the cover glass to be thinner, as it is supported by a layer of hardened adhesive. This significantly decreases the total display weight, resulting in a much lighter display that is easier to handle and transport.

Optical bonding is the only real bonding. While some displays claim to use alternative bonding processes, only an optically bonded display is truly bonded. Other methods are no different from the air bonding process, which uses tape to attach the LED cell to the glass, making the air gap inevitable. Only an optically bonded display can provide all of these benefits by completely eliminating the air gap.

Although optical bonding is common in high-end smartphones, it is harder to apply the use of such technology to larger screens like interactive displays. Newline Interactive employs the most advanced technology in optical bonding to evenly bond displays and offer optically bonded displays as large as 86”.

Newline proudly incorporates optical bonding technology to deliver interactive displays with the best user experience available. Optically bonded displays are more durable, easier to handle and transport, and provide a better viewing and touch experience for everyone. Newline’s line of optically bonded displays includes the X, MIRA and NAOS IP series.